Inflation: its economic impact and implications on supplychains

The pandemic emergency that arose in the beginning of 2020 caused lot of problems, amongst the most widely known : supplychain bottlenecks and economic slowdown of the global economy.

The ECB (European Central Bank) started an aggressive quantitative easing and issued lots of debt to support th economy of the EU. The ECB has printed far too much money in ensamble with the FED (Federal Reserve-Central Bank of USA).

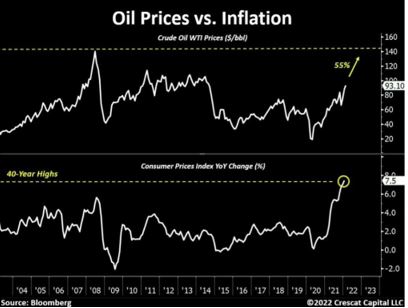

This “emergency monetary policy” has brought inflation to 40 year highs , with no sign of stopping any time soon. Both leaders, of these two previously mentioned central banks, changed their public opinion from something that appears to be transitory to something that will be prolonged well into 2023.

This has clear impact on the costs of freight transports, which already have risen quite a lot due to supply chain disruptions. The issue is that inflation is not on a particular basked of goods, rather it has impacted the whole economy. Short term manufacturing companies needed to pay more their transports in an effort to stay afloat during the pandemic. However this is clearly not sustainable in the long term, as inflation and freight costs are eroding companies margin on sales. Inflation in the USA has risen to 7.7% in January of 2022 and in EU zone inflation has risen to 5.5%.

There are growing concerns that central banks will not be able to significantly take action to reduce inflation. The effect on the economy is devastating, as manufacturing companies are experiencing rises in costs of raw materials, energy and cost of labor. Among the energy sector, besides the price of natural gas, the price of gasoline is high, but could go much higher. In 2008 inflation wasn’t as high but the price of gasoline was much higher than it is now.

The most worrysome are the cost increases, as now the average consumer is in “saving” mode and isn’t willing to spend more on certain goods, as they cannot afford them and have to change consumer behaviour with regards to their consumption habits.

For the above mentioned reasons manufacturing companies should start to look towards alternative solutions to their logistics and transports in order to reduce, where possible their costs. One of these solutions, the most evident, is intermodal transports , which not only are most often cheaper but also sustainable and innovative.

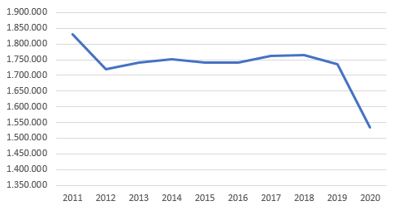

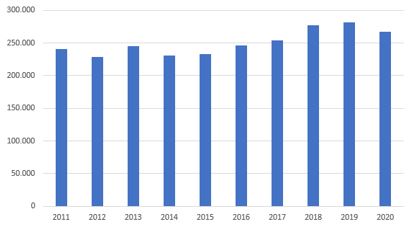

The longer the transit the more intermodal solutions become more attractive in terms of cost efficiency. If years ago the only solution was pure train transports, since you couldn’t load intermodal trailers on it, now we can see a shift away from pure train and into intermodal as being more flexible and cost efficient means of transport. We can see from the graphs below this clear shift away from pure train and into intermodal transports. From the graphs below we convey what mentioned above. Figure 1 shows a net decrease in transports done exclusevly via train only, meanwhile figure 2 shows an overall increase in transports done with intermodal solutions.

Thousands of tonnes transported via train only

Figure 1

Thousands of tonnes transported with intermodal solutions

Figure 2

Given the following economic contex, we suggest to consider alternative solutions for your transports, in order to avoid supplychain bottlenecks and reduce the impact of price increases on sales revenue.

PUBLISHED ON